Welcome to Otter Lake Woodwinds, where you’ll find the fruits of my labor (check back regularly for more added). I’m Jeff Burris, and I’ve followed how different makers craft their Native American-style Flutes and other woodwinds inspired by tradition.

The difference between a Native American flute and a Native American style flute is both a respectful and a legal distinction. It is unlawful for any of us to represent a product in a way that insinuates it was made by enrolled, Native American tribal members, unless we are, which I am not, so I say I make Native American style flutes, so that I do not have to excessively repeat any disclaimers about not being Native American. The name of the flute is often used to describe modern versions that may bear relatively little similarity to museum relics, but its whistle mechanism and related features are distinctive and it’s only fair and respectful to always acknowledge the endangered cultures that invented its certain form. There are also modern standard defaults for scales, and things that will be generally expected from the term Native American Flute (with or without “-style”) if not specified otherwise. These modern standards came over time, the latest of which is likely the pentatonic minor scale occupying its primary fingerings, which is thought to have exploded into popularity following Michael Graham Allen’s flutes in the bloom of the New Age movement. I feel this is true about the flutes, and have injected into much conversation that pentatonic minor scale was used very much in earlier Western media like radio shows and old movies and TV, so the general public was ready to instinctively associate it with the “otherness” of a different culture by the time the 70’s rolled around. Apparently, though, Allen was inspired by his Japanese Shakuhachi flute of the same scale.

If you want a flute made by a Native American, I can direct you to someone with flute craft rooted in their family or tribal history. I work very hard to bring you the best quality possible, having adopted techniques from makers who differ greatly from one another, from Indians to aerospace guys, and one man who is both (early on, I was inspired by Jim Gilliland to makes nests separately and attaches them).

I was inspired greatly to follow the craft by Blue Bear videos, in the beginning. Indigenous tribal member Charlie Mato-Toyela welcomes anyone to the craft and even the very trade itself (as a competitor!) if they want to. The man I owe the most to is Jon Norris, as he made himself available for me to consult with at length about minutia, daily, for over a year, until I was consistent, including use of the postal service for hands-on trials. I was making lesser-performing flutes my first week, but the nuances that collectors and avid players look for took fifty times that much time for me to reliably expect from each flute.

My lathe is fully manual aside from the electric spindle (I use oldschool HSS hand chisels and gouges, and have no cross slide) and I do hours of powerless, hand work finishing each flute.

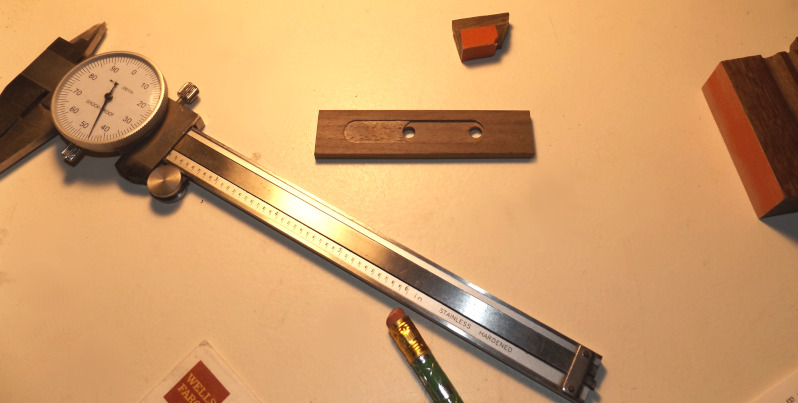

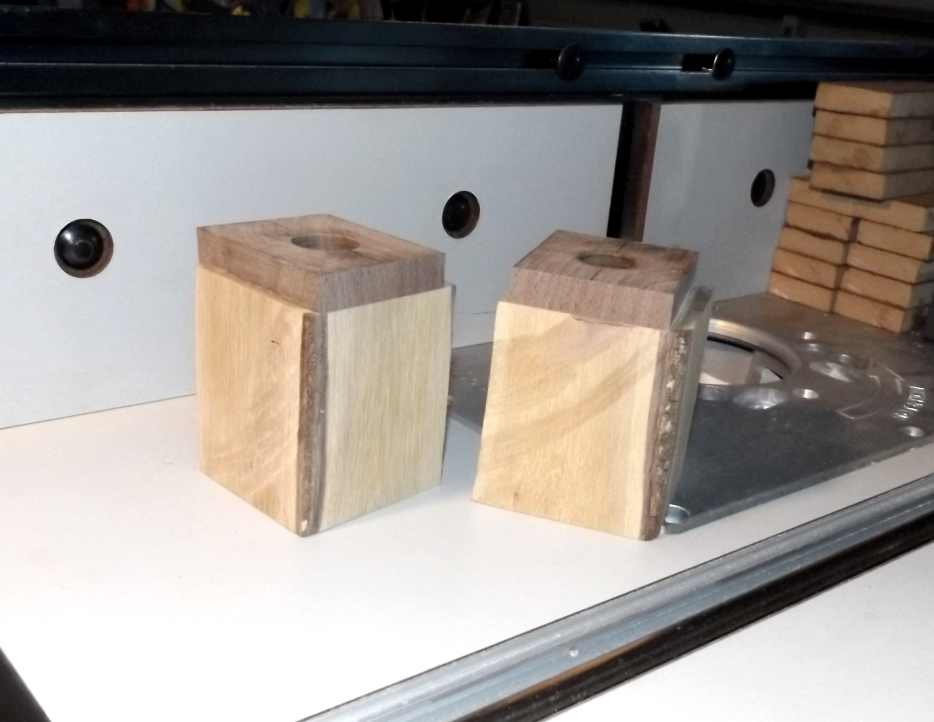

On the other hand, since I obsess over consistent results and was raised in military and aerospace parts machine shops, the “nest” (with the flue) is something I like to keep within mil-spec tolerances. I have a small, precision milling machine with hand cranks — not at all automated, but precise with hand-dialed X and Y cross slides and DRO’s. I can often be seen incorporating a separately-milled nest that I can work on, by itself, and then add to the flute. It gets more and more manual, hands-on from there on, in the process.

While my typical flute is based on the standard pentatonic minor scale, I also strive for as chromatic of a flute as possible, ideally capable of well over an octave of reliable, predictable semitones, all possible from the 6 holes (with the lesser-common notes using, to me, the most intuitive cross-fingerings possible). There should be virtually no hissing sound or excess “airiness”, and very controlled overblow (ability to blow harder than some flutes allow, before cracking into a higher note from excess pressure). Some of these things were accomplished with Edward Kort’s Woodwind Instrument Designer software whereas others required advice, trial and error, and/or a little muscle memory with the hand-tooling.

I will say “voicing” of a flute is subjective and personal. There is no right or wrong or “better” in this regard, at least when newbie mistakes or early challenges are all in the past. A very small minority of flutes strive for utmost clarity, like a recorder or some low whistles. My own tastes run similarly to the majority of other makers and players of NAF, and that includes room for a little reedy “woodiness”. Literally by design. I only encountered the clarity search demographic after a couple of years. It’s all preference, and my main line of flutes will always sound like what I imagine sounds “authentic”, spawning fantasy and culture in my imagination. Like a touch of panflute (not too much).

Instructor Martha Markusen said in 2023 that she loved how she could play with ample pressure and volume while remaining in tune, and that the voice was remeniscent of her MG Allen flute. My core design was originally based on Jon Norris and WID software by Edward Kort.

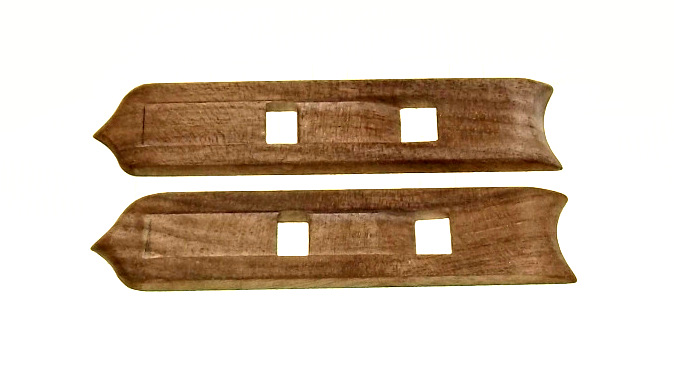

See that mouthpiece being turned along with the rest of the flute, made of different woods ?

With some instruments, those are just flat, pressed against each other and glued. Mine have a tenon inserted (or carved) to lock it tight forever (and glued):

My flutes take many hours (and then some) each, to make. God has blessed me with a growing number of folks who consider it quality work for an affordable price… quality enough, at least, to hear it got played at a small gathering by a very discerning master of the trade, and from whom I’ve had the blessing of receiving immeasurable guidance. Hearing that Jon Norris showed my flute at his own flute circle was the real beginning of my flute journey. He had crafted and purveyed his own fine flutes to musical professionals for over a decade, and knowing he’d play that flute and say he’d been helping me… that was a real acknowledgement boost telling me to get to making chips and stop with the analysis paralysis.

One unusual flute part material Tina and I grew, ourselves:

Many people consider the Mimosa tenuiflora (Mimosa hostilis or Ayahuasca) tree sacred or very special. I have cared for one on the property near the river cane property for many years. I would never cut it for wood, but we got a bunch when Florida decided to prune some for me with an infrequent, hard freeze and it died back a bunch all on its own (despite sheets tied over the whole shrub tree), needing long-dead branches sawn off.

So I very occasionally use it for parts for people who find it worth the extra expense (it is rare and very difficult to work with but ends up great). Here are Ayahuasca mouthpiece blanks ready for tenons and turning (a couple of years ago…I still have some but it’s temperamental for the maker…stable/safe enough once it’s made:

…and a “bird” or block (totem-inspired) carved out of the same mimosa wood:

Whatever your path, I’m glad it brought you here, now. Thanks for visiting!

— Jeff Burris —

info@otterlakeflutes

P.S.

Say, “Hi”, to our beloved mascott (in lieu of a real otter!): our giant sulcata tortoise, “Bonsai” —

Contact Me: info@otterlakeflutes.com